- Home

- Fiber Cable & Tools

- Drop Cable

- FTTH Drop Cable

FTTH Drop Cable

With the development of fiber optic communication, FTTH has been the final solution of fiber-optic networks. It adapts to the demand for high speed and massive transmission of optical network signals from many users. In FTTH access projects, common indoor fiber optic cable cannot meet the requests of indoor distribution in mechanical ability and tensile properties. Under the situation of the market’s needs, FTTH drop cable with low bending radius and high intensity has been widely used in FTTH’s access network.

Extra Description

Applications

- FTTx FTTH project for indoor cable

- Installation in a small bending environment

Features

- Low purchasing and construction costs

- Soft and flexible, good bending performance

- Simple structure, compact and lightweight, and high practicability

- Flame retardant LSZH jacket meets relevant fire protection requirements in the indoor environment

- Two parallel strength members ensure good performance of crush resistance to protect the fiber

- Special low-bend-sensitivity fiber provides high bandwidth and excellent communication transmission property

- Novel notch design for easy stripping, and easy connection without splicing or with splicing, simplify the installation and maintenance

- Drop Cable Patch Cord/Pigtail Data Sheet

Item Code Information

Specifications:

| Connector Type | SC/FC/ST/LC/MU/SMA905/Nil(non-connector)/ E2000/MTRJ(W/O)/MTRJ(W)/DIN/FDDI/ESON |

| Polishing Type | SM: UPC/APC |

| Working Wavelength (nm) | 1310~1650 |

| Strength Member of Cord | S-Steel/F-FRP (Fiberglass Reinforced Plastics) |

| Sheath Material | PVC/LSZH/OFNR or else |

| Insertion Loss (dB) | <0.4 |

| Return Loss (dB) | UPC: ≥55, APC≥60 |

| Repeatability (500 times) (dB) | ≤0.2 |

| Bending Radius (mm) | ≥15 |

| Tensile Strength (kg/100mm) | ≤8 |

| Working Temperature (℃ ) | -20℃ ~+80℃ |

| Storage Temperature (℃ ) | -20℃ ~+80℃ |

| Working Humidity | <90%RH |

| Sheath Diameter (mm) | 2*3.1 or 2*5 |

| Sheath Color | White/black/customization |

| Connector Length (mm) | 50 |

| Fiber Length (m) | customization |

FTTH Drop Cable

with the development of fiber optic communication, FTTH has been the final solution of fiber optic network. It adapts to the demand on high speed and massive transmission of optical network signals from many users. In FTTH access projects, common indoor fiber optic cable cannot meet the requests of indoor distribution in mechanical ability and tensile properties. Under the situation of market’s needs, FTTH drop cable with low bending radius and high intensity has been widely used in FTTH’s access network.

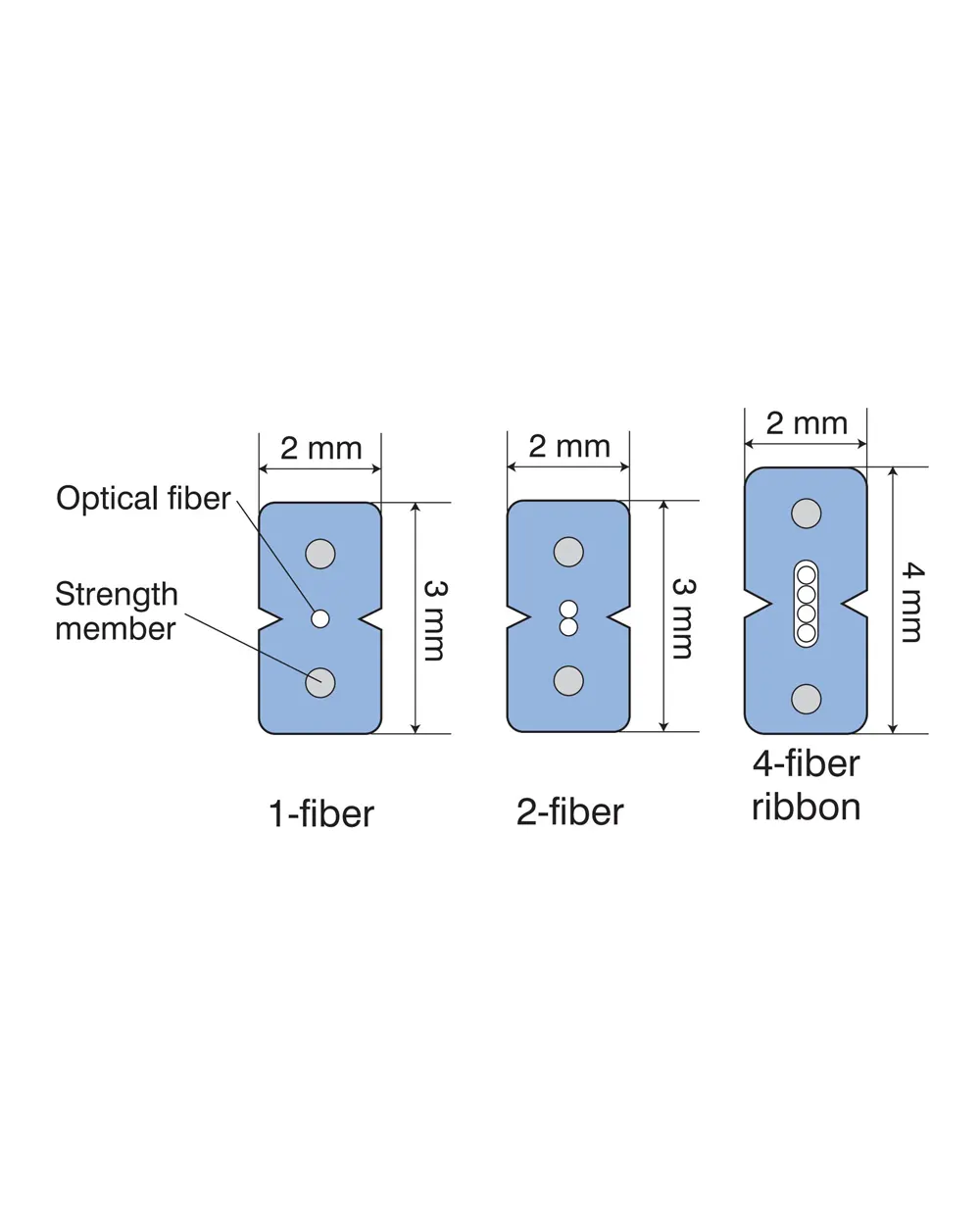

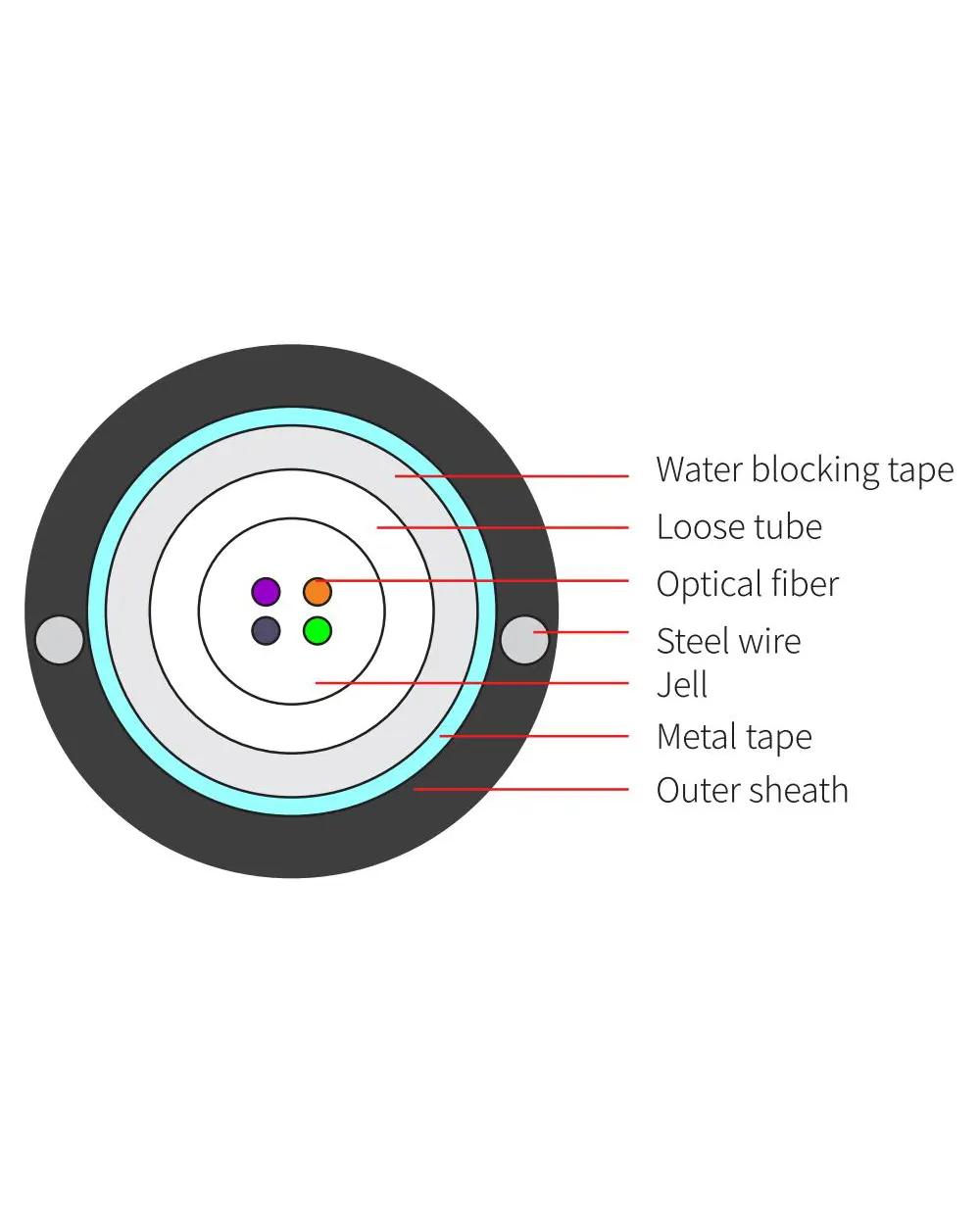

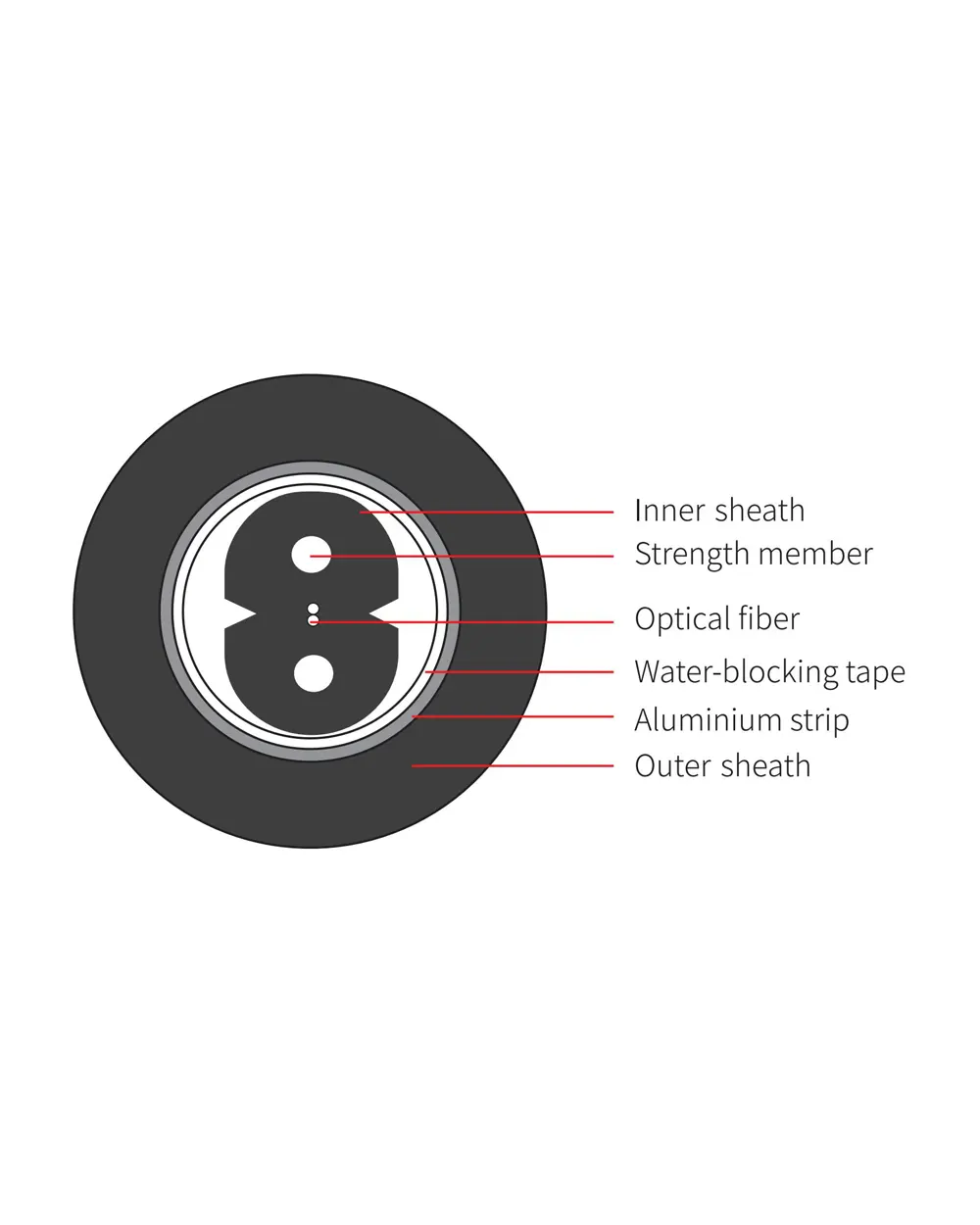

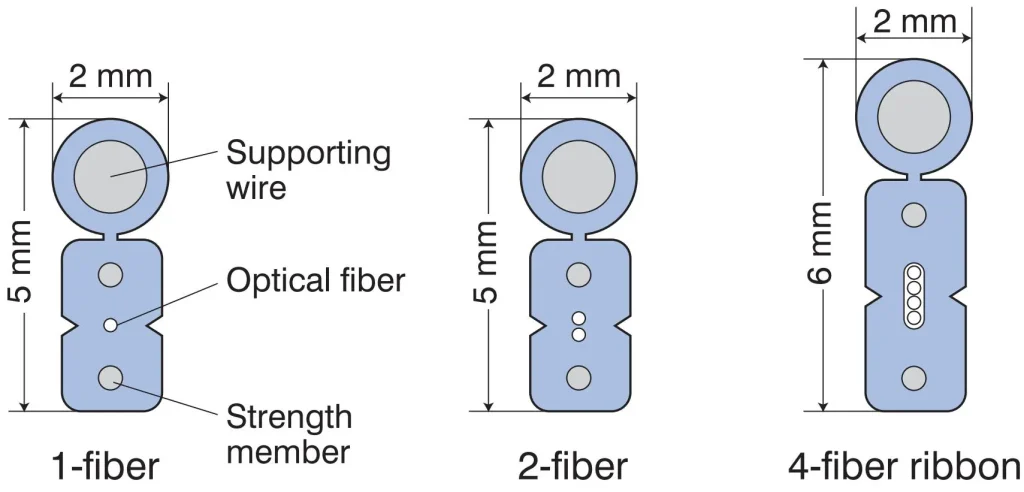

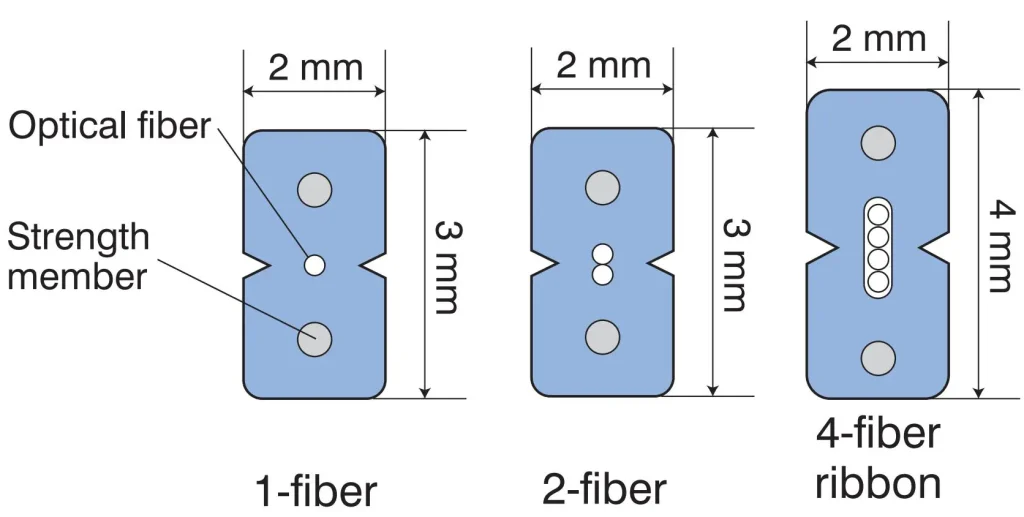

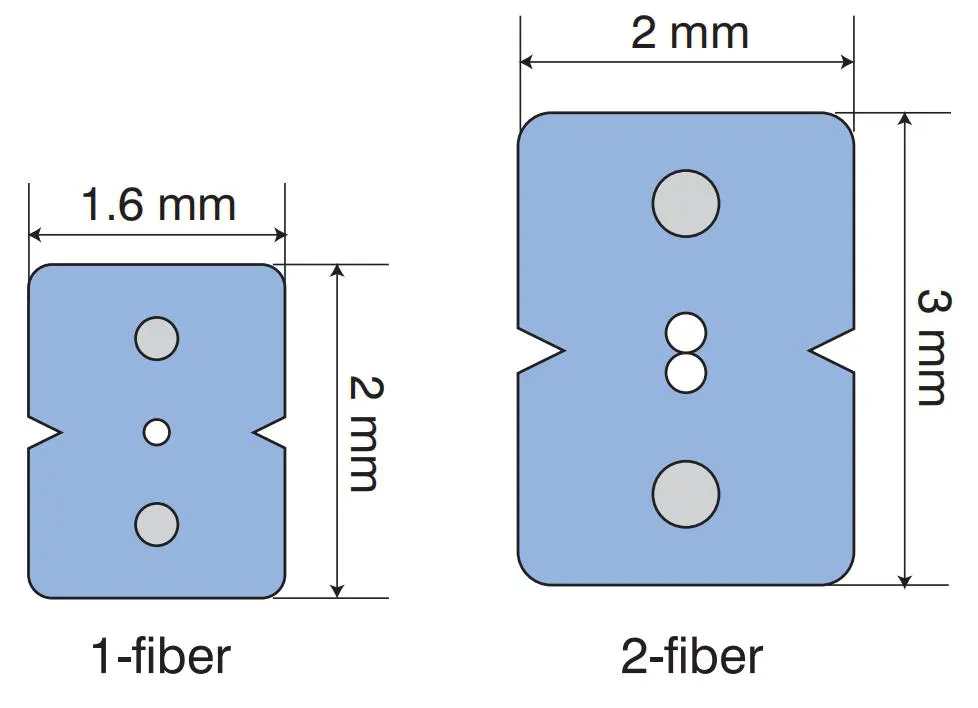

Cable Structure:

The optical fiber unit is positioned in the center. Two parallel strength members are placed at two sides. Then, the cable is completed with a jacket.

Features:

- Low purchasing and construction costs

- Soft and flexible, good bending performance

- Simple structure, compact and light weight, and high practicability

- Flame retardant LSZH jacket meets relevant fire protection requirements in indoor environment

- Two parallel strength members ensure good performance of crush resistance to protect the fiber

- Special low-bend-sensitivity fiber provides high bandwidth and excellent communication transmission

property - Novel notch design for easy stripping, and easy connection without splicing or with splicing, simplify

the installation and maintenance

Applications:

- FTTx FTTH project for indoor cable

- Installation in small bending environment

Environmental Characteristics:

| Operation&Installation Temperature | -20°C~+60°C |

| Storage Temperature | -40°C~+70°C |

Standard Drop Cable Characteristics:

| Fiber Count | 1 fiber | 2 fibers | 4 fibers | 8 fibers |

| Cable Dimension (mm) (Without Suspension Wire) | 2.0×3.0 | 2.0×4.0 | 2.5×4.0 | |

| Cable Dimension (mm) (With Suspension Wire) | 2.0×5.0 | 2.0×6.0 | 2.5×6.0 | |

| Cable Weight (kg/km) (Without Suspension Wire | 10 | 15 | ||

| Cable Weight (kg/km) (With Suspension Wire | 19.5kg/km+15% | 35kg/km+15% | ||

| Strength Member | Steel: 0.4 FRP: 0.45 | mm (Diameter) | ||

| Tension Performance (N) | Short Term | Long Term | ||

| 200 (without suspension wire) 600 (with suspension wire) | 100 (without suspension wire) 300 (with suspension wire) | |||

| Crush Resistance (N/100mm) | Short Term | Long Term | ||

| 1000 (without suspension wire) 2200 (with suspension wire) | 500 (without suspension wire) 1000 (with suspension wire) | |||

| Spam | Maximum 60 meters | |||

| Minimum Bending Radius (mm) | Dynamic | Static | ||

| 30 (without suspension wire) 240 (with suspension wire) | 15 (without suspension wire) 120 (with suspension wire) | |||

Low Friction drop cable

Geometrical Characteristics:

| Cladding Diameter | — | 125.0±0.7 | [μm] |

| Cladding Non-Circularity | — | ≤1.0 | [%] |

| Coating Diameter | — | 240-250 | [μm] |

| Coating-Cladding Concentricity Error | — | ≤12.0 | [μm] |

| Coating Non-Circularity | — | ≤5.0 | [%] |

| Core-Cladding Concentricity Error | — | ≤0.6 | [μm] |

| Curl(radius) | — | ≥4 | [m] |

| Delivery Length | — | Up to 50.4 | [km/reel] |

| Environmental Characteristics | 1310nm, 1550nm & 1625nm | ||

| Temperature Dependence Induced Attenuation | -60℃ to +85℃ | ≤0.05 | [dB/km] |

| Temperature-Humidity Cycling Induced Attenuation | -10°C to +85°C, 98% RH | ≤0.05 | [dB/km] |

| Water Immersion Dependence Induced Attenuation | 23°C, for 30 days | ≤0.05 | [dB/km] |

| Damp Heat Dependence Induced Attenuation | 85°C and 85% RH, for 30 days | ≤0.05 | [dB/km] |

| Dry Heat Aging | 85℃, for 30 days | ≤0.05 | [dB/km] |

Transmission Characteristics:

| Fiber Type | G.652.D | G.657.A1/A2 | G.657.B1/B2 | |||

| Wavelength (nm) | 1310 | 1550 | 1310 | 1550 | 1310 | 1550 |

| Attenuation (dB/km) | ≤0.45 | ≤0.40 | ≤0.45 | ≤0.35 | ≤0.45 | ≤0.35 |

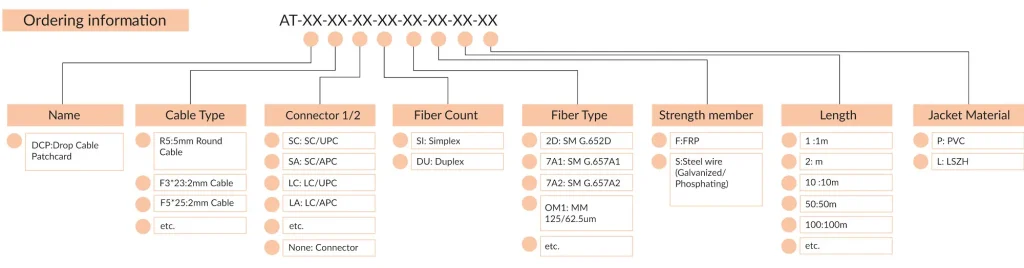

Ordering information