MPO-12 Connectors What Are They?

If you’re involved in fiber optic networks or data centers, you’ve likely heard of MPO connectors. But have you ever come across the MPO-12 connector? It’s a game-changer in the world of high-speed data transmission, packing 12 individual optical fibers into a single, compact unit. This connector is designed to support the fast, reliable data flow needed in today’s high-demand networks, especially where space is limited but speed is essential.

So, what exactly is an MPO-12 connector? Think of it as a multi-fiber solution, designed for the modern, high-density network. It allows you to connect 12 fibers all at once—making it an essential tool for network engineers looking to boost bandwidth without using up too much space.

Table of Contents:

How Does an MPO-12 Connector Work?

At its core, the MPO-12 connector is all about efficiency and speed. Here’s how it works:

When you plug the MPO-12 connector into its counterpart, you’re connecting 12 separate optical fibers. Each of these fibers carries data in the form of light signals, which means faster, more reliable data transmission. The key is that the MPO connector allows all 12 fibers to work simultaneously, so you’re not losing time with separate connections.

The connector’s design makes installation a breeze—it’s built to simply push on and lock into place, allowing you to easily set up your connections without any hassle. And, because it’s designed for high-density installations, the MPO-12 saves you a ton of space, which is a huge advantage in crowded environments like data centers.

What’s Inside an MPO-12 Connector?

MPO-12 connectors are built to last, and that’s thanks to their high-quality materials. Here’s a breakdown of what goes into these connectors:

1. Connector Housing: This is the outer shell of the connector, usually made of durable plastic like PBT (Polybutylene Terephthalate) or LCP (Liquid Crystal Polymer). These materials are tough and heat-resistant, which makes them perfect for protecting the delicate fibers inside.

2. Ferrules: Inside the connector, ceramic ferrules (typically made from zirconia) hold the 12 fibers in place. These ferrules ensure that each fiber is perfectly aligned for optimal signal transfer.

3. Alignment Pins: Think of these as tiny guides that make sure the fibers line up perfectly when the connector is plugged in. These pins are usually made from stainless steel for durability.

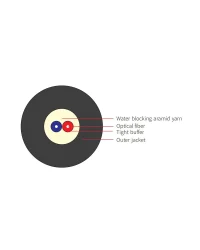

4. Cable Sheath: The cables attached to the MPO-12 connector are protected by an outer sheath, often made from PVC or LSZH (Low Smoke Zero Halogen) materials to offer both flexibility and fire resistance.

Why You’ll Love MPO-12 Connectors?

The materials used in MPO-12 connectors play a significant role in their performance and durability. Here’s why:

– Precision: High-quality materials like zirconia ceramic for ferrules help maintain the alignment of the fibers. This ensures minimal signal loss and maximum efficiency—crucial for high-speed networks.

– Durability: The materials used, like stainless steel for alignment pins and PBT for housing, are resistant to wear and tear, making them perfect for environments where connectors need to stand up to constant use and harsh conditions.

– Environmental Resistance: Whether your connectors are in a data center or an outdoor telecom installation, they’ll need to perform under varying conditions. High-quality materials ensure the connectors are resistant to heat, moisture, and chemicals.

Why Does Material Matter for MPO-12 Connectors?

MPO-12 connectors pack a lot of punch in a small package. Here are the standout features that make them so popular:

– Space-Saving Design: The MPO-12 packs 12 fibers into one connector, so you can handle more connections in less space. This is a huge deal for data centers or anywhere you need to maximize space while keeping connections clean and tidy.

– Quick and Easy to Use: Thanks to the push-on, pull-off mechanism, you can install and remove connectors quickly. No complicated tools or processes, just simple and reliable connectivity.

– Versatility: Whether you’re using single-mode or multi-mode fibers, the MPO-12 connector has you covered. It’s adaptable to different types of fiber optic networks, offering a lot of flexibility.

– High-Speed Data Transfer: The MPO-12 connector supports high-speed data transmission, making it perfect for applications that require bandwidth-intensive connections, like 10G, 40G, or even 100G networks.

What Are the Advantages of Using MPO-12 Connectors?

So, why should you consider using MPO-12 connectors in your network setup? Here are a few good reasons:

– Efficient Use of Space: Because MPO-12 connectors allow you to connect 12 fibers at once, you don’t have to deal with a maze of individual connectors. This is a real space-saver in high-density environments.

– Improved Data Transmission: With 12 fibers working in unison, you get better bandwidth and faster data transfer speeds. This is essential as we rely more and more on cloud-based applications and data-heavy content.

– Cost-Effective: At first glance, MPO-12 connectors might seem more expensive, but they can actually save you money in the long run. They reduce the need for multiple connectors and allow you to handle more data with fewer components.

– Scalability: If you need to expand your network, MPO-12 connectors make it easy to do so without a huge overhaul. You can scale up your network by adding more fibers without taking up extra space.

Are There Any Disadvantages to MPO-12 Connectors?

As great as MPO-12 connectors are, they do have a few drawbacks:

– Polarity Can Be Tricky: If you don’t manage the polarity correctly, it can cause connectivity issues. It’s important to make sure that the fibers are properly aligned, especially when working with high-speed networks.

– Initial Setup Cost: While MPO-12 connectors are cost-effective in the long run, the upfront cost might be higher than traditional fiber connectors. This could be a consideration for smaller projects or smaller budgets.

– Installation Complexity: While they’re easy to install once you get the hang of it, first-time installation can be a little tricky if you’re not familiar with fiber optic connectors. Training or guidance may be needed.

Where Can You Use MPO-12 Connectors?

MPO-12 connectors are perfect for applications where you need high-density, high-performance fiber optic connections. Here are a few places where they shine:

– Data Centers: In data centers, where space and speed are crucial, MPO-12 connectors help manage fiber optic connections in the most efficient way possible.

– Telecom Networks: Whether it’s for backhaul or main telecom connections, MPO-12 connectors are great for handling the high-capacity demands of modern telecom systems.

– Enterprise Networks: In large office buildings or multi-building campuses, MPO-12 connectors ensure smooth, high-speed data flow across different departments or floors.

– 5G Networks: As 5G continues to grow, MPO-12 connectors play a big role in handling the massive bandwidth required for these next-gen networks.

How to Choose the Right MPO-12 Connector for Your Needs?

Choosing the right MPO-12 connector isn’t as complicated as it might seem. Here are a few tips to guide your decision:

1. Consider the Fiber Type: Are you using single-mode or multi-mode fibers? Choose an MPO-12 connector that matches the fiber type you’re working with.

2. Get the Polarity Right: Make sure you’re using the right polarity configuration for your network. You can choose from Type A, Type B, or Type C, depending on your setup.

3. Think About Your Environment: If your network will be exposed to harsh conditions (high heat, moisture, etc.), make sure to choose connectors with materials that offer durability and resistance.

4. Compatibility: Always double-check that the MPO-12 connector you select is compatible with your equipment. This includes the right gender (male or female) and fiber count.

5. Ease of Installation: If you need a quick, hassle-free installation, consider pre-terminated MPO-12 connectors that save you time and effort.