- Home

- Passive Components

- Fiber Optic Patchcord and Pigtail

- Fiber Optic Patch Cord and Pigtail

Fiber Optic Patch Cord and Pigtail

Fiber Optic Patch Cord is also called fiber jumper, fiber patch lead, or fiber optic cable assemblies.

Fiber Optic Patch Cord/Fiber Jumper and Fiber Optic Pigtail are mainly used for providing connectivity between fiber optic devices, Optical Distribution Frame ODF, Fiber Optic Patch Panel, Optical Distribution Box, etc. in telecom, cable TV, and FTTH.

Extra Description

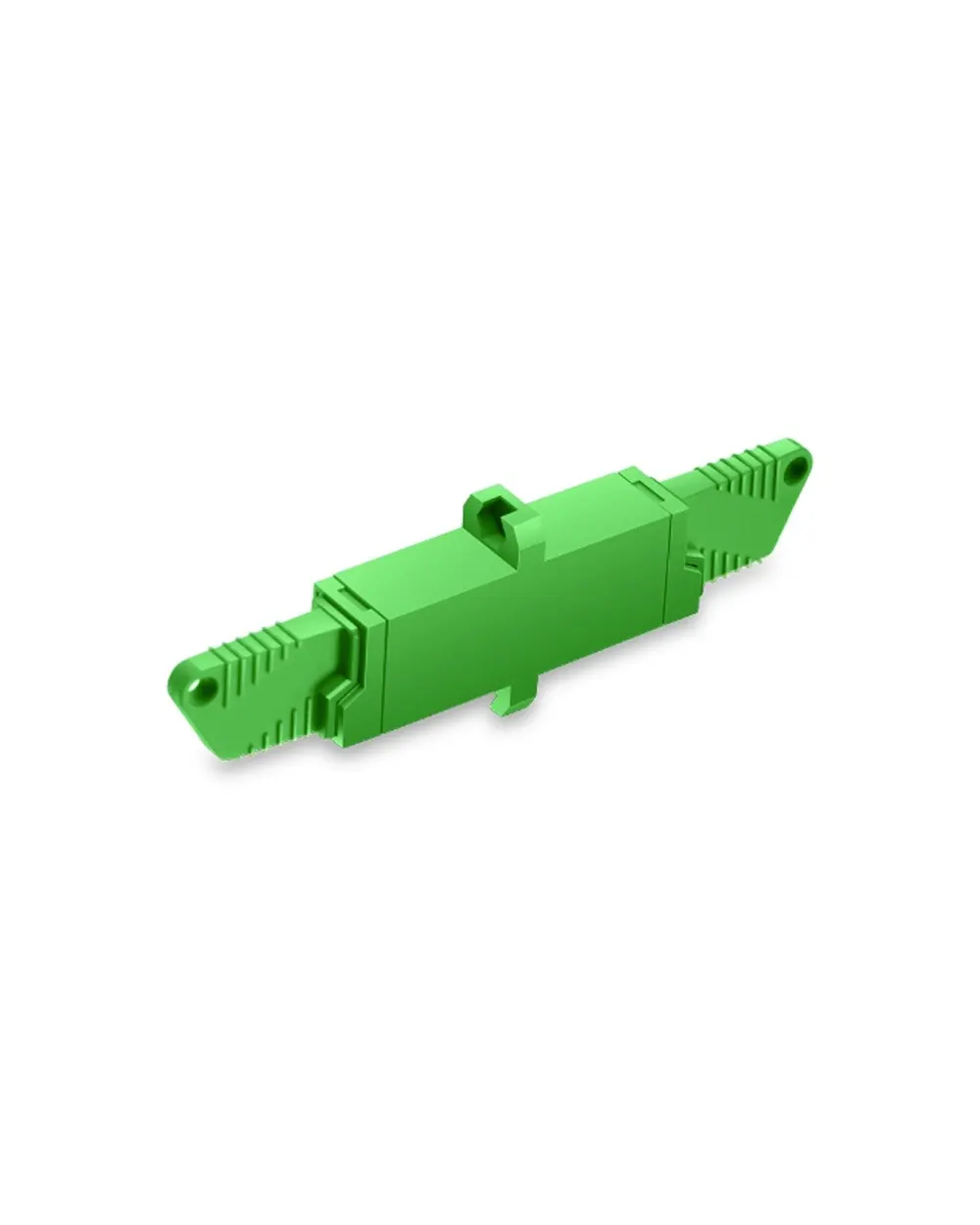

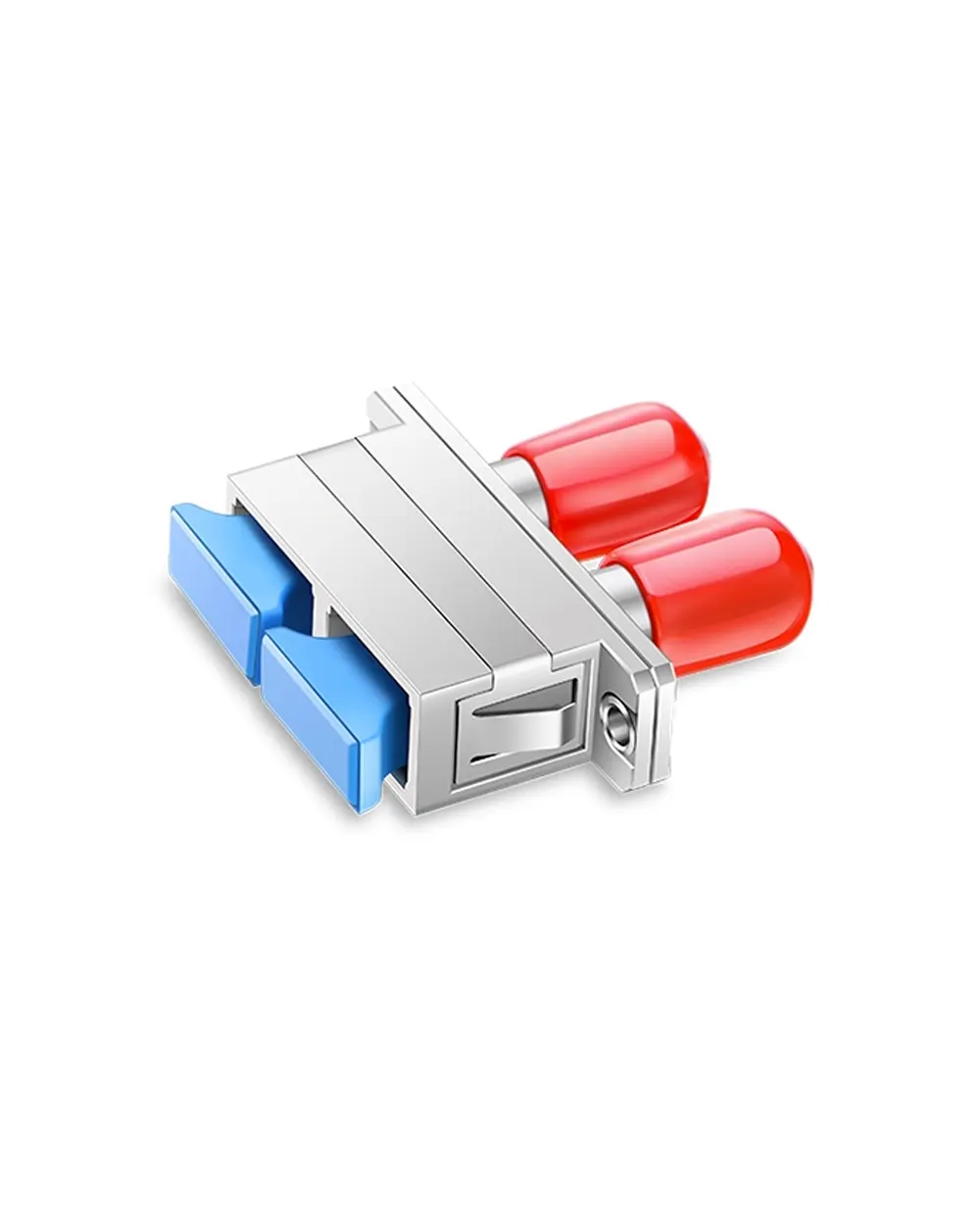

We offer a wide range of Fiber Optic Patch Cords and pigtails because of different connectors and fibers, SC jumper, FC jumper, LC jumper, ST jumper, MU jumper, MTRJ jumper, E2000 jumper, MPO jumper, and hybrid patch cords, SC to FC patch cord, SC to LC patch cord, FC to LC patch cord for example; there are single-mode Fiber Optic Patch Cord, multi-mode Fiber Optic Patch Cord, OM3 10G Fiber Optic Patch Cord, etc.

In the meanwhile, we offer Corning fiber jumpers (Corning fiber patch cords) to meet customers’ specific requirements.

The combination of a precision ceramic ferrule of fiber optic connector, reliable fiber, and cable performance provides consistent long-term mechanical and optical performance for fiber optic connectivity.

Features

- OEM order available

- High-temperature stability

- Excellent mechanical endurance

- Excellent polished and 100% tested

- Low insertion loss and high return loss

Applications

- CATV

- LAN & WAN

- Telecommunication networks

- FTTX, FTTH (Fiber to the Home)

- Fiber Optic Patch Cord and Pigtail Data Sheet

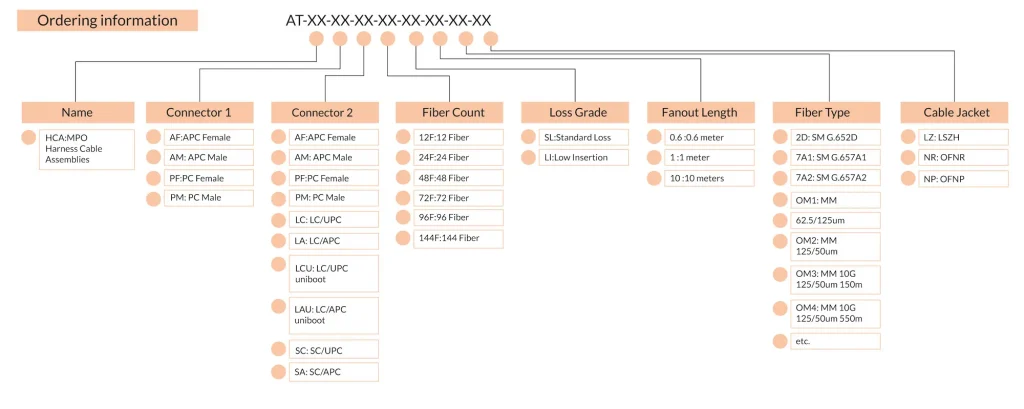

Item Code Information

Connector Specifications:

| Mode | SM | MM | |

| Polishing | APC | UPC | UPC |

| Insertion Loss | ≤0.3dB | ≤0.3dB | ≤0.3dB |

| Return Loss | ≥60dB | ≥55dB | ≥35dB |

| Interchangeability | ≤0.2dB | ||

| Salt Spray | ≤0.2dB | ||

| Repeatability | ≤0.1dB (1,000 times) | ||

| High Temperature | ≤0.2dB (+85°C 168 hours) | ||

| Low Temperature | ≤0.2dB (-40°C 168 hours) | ||

| Temperature Cycle | ≤0.2dB (-40°C~85 °C 21 cycles 168 hours) | ||

| Humidity | ≤0.2dB (95% 75°C 168 hours) | ||

| Apex Offset | 0~50um | ||

| Radius of Curvature | 7~25mm | ||

| Undercut | -50~50mm | ||

| Durability | ≥1,000 matings | ||

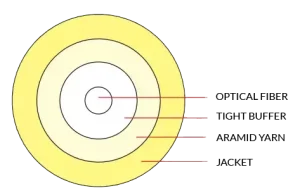

| Tensile Strength (Standard is Polyester) | Aramid Yarn: ≥90N (3.0mm), ≥70N (2.0mm) | ||

| Polyester: ≥50N (3.0mm), ≥40N (2.0mm) | |||

| Vibration | ≤0.1dB (10-55Hz 1.5mm) | ||

| Operating Temp. | -40°C~+80°C | ||

Note: Insertion loss 0.2dB and 0.1dB (master cord/reference cable) is also available.

| TightBufferedFiber | Simplex Patchcord Cable | ||||||

| For pigtails | For patch cords | ||||||

|  | ||||||

| Fiber Count | Cable Diameter | Crush Resistance (Short) | Minimum bend radius (Dynamic) | Fiber Count | Cable Diameter | Crush Resistance (Short) | Minimum bend radius (Dynamic) |

| 1 | 0.9mm | 100 | 60 | 1 | 2.00 | 500 | 60 |

| 1 | 60 | 500 | 60 | ||||

Transmission Properties:

| Fiber Type | G652 SM (1310nm/1550nm) | G657 SM (1310nm/1550nm) | 62.5um (850nm/1300nm) | 50um (850nm/1300nm) |

| Maximum Attenuation (dB/km) | 0.4/0.3 | 0.4/0.3 | 3.5/1.5 | 3.5/1.5 |

| Typical Attenuation (dB/km) | 0.36/0.22 | 0.36/0.22 | 3.0/1.0 | 3.0/1.0 |

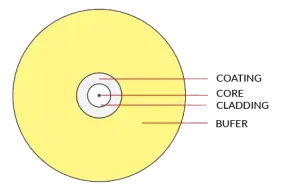

Optical Characteristics:

| Cladding Diameter | — | [dB/km] | |||

| Cladding Non-Circularity | — | [dB/km] | |||

| Coating Diameter | — | [dB/km] | |||

| Coating-Cladding Concentricity Error | — | [dB/km] | |||

| Coating Non-Circularity | — | [dB/km] | |||

| Core-Cladding Concentricity Error | — | [dB/km] | |||

| Curl(radius) | — | [ps/(nm·km)] | |||

| Delivery Length | — | [ps/(nm·km)] | |||

| Environmental Characteristics | 1310nm, 1550nm & 1625nm | ||||

| Temperature Dependence Induced Attenuation | -60℃ to +85℃ | ≤0.05 | [dB/km] | ||

| Temperature-Humidity Cycling Induced Attenuation | -10°C to +85°C, 98% RH | ≤0.05 | [dB/km] | ||

| Water Immersion Dependence Induced Attenuation | 23°C, for 30 days | ≤0.05 | [dB/km] | ||

| Damp Heat Dependence Induced Attenuation | 85°C and 85% RH, for 30 days | ≤0.05 | [dB/km] | ||

| Dry Heat Aging | 85℃, for 30 days | ≤0.05 | [dB/km] | ||

Geometrical Characteristics:

| Cladding Diameter | — | [dB/km] | |||

| Cladding Non-Circularity | — | [dB/km] | |||

| Coating Diameter | — | [dB/km] | |||

| Coating-Cladding Concentricity Error | — | [dB/km] | |||

| Coating Non-Circularity | — | [dB/km] | |||

| Core-Cladding Concentricity Error | — | [dB/km] | |||

| Curl(radius) | — | [ps/(nm·km)] | |||

| Delivery Length | — | [ps/(nm·km)] | |||

| Environmental Characteristics | 1310nm, 1550nm & 1625nm | ||||

| Temperature Dependence Induced Attenuation | -60℃ to +85℃ | ≤0.05 | [dB/km] | ||

| Temperature-Humidity Cycling Induced Attenuation | -10°C to +85°C, 98% RH | ≤0.05 | [dB/km] | ||

| Water Immersion Dependence Induced Attenuation | 23°C, for 30 days | ≤0.05 | [dB/km] | ||

| Damp Heat Dependence Induced Attenuation | 85°C and 85% RH, for 30 days | ≤0.05 | [dB/km] | ||

| Dry Heat Aging | 85℃, for 30 days | ≤0.05 | [dB/km] | ||

Mechanical Specifications:

| Proof Test | — | ≥9.0 | [N] | ||

| — | ≥1.0 | [%] | |||

| — | ≥100 | [kpsi] | |||

| Macro-bend Induced Attenuation | 100 Turns Around a Mandrel of 30 mm Radius | 1625nm | ≤0.05 | [dB] | |

| 100 Turns Around a Mandrel of 25 mm Radius | 1310nm and 1550nm | ≤0.05 | [dB] | ||

| 1 Turn Around a Mandrel of 16 mm Radius | 1550nm | ≤0.05 | [dB] | ||

| Coating Strip Force | [ps/(nm·km)] | ||||

| [ps/(nm·km)] | |||||

| Dynamic Fatigue Parameter(nd) | |||||

Ordering information: